Algae for Air Purification

Air Pocket

Air Pocket is an innovative material engineered to purify our air within our vehicles. Grounded in hands-on research and automotive future-forecasting, this project demonstrates how vehicles can evolve into carbon-absorbing entities, highlighting the endless possibilities of nature.

Time Frame

8 Weeks– June-August 2023

Team: 2 People

A collaboration with Hyundai Motor Group CMF Designer– Jiyeon Lee

Skills: Market Analysis, User-centered Research, Trend Analysis, Design Systems, Parametric 3D CAD Software (Fusion 360, Rhino, 3D-print-prototyping)

Final Product

Through extensive hands-on research, we developed a modular material that filters polluted air. Air Pocket would be integrated into a hydrogen-powered electric car, taking advantage of the water released from the engine. After use, this material would be recycled for the use on car interior parts.

To learn more, click on the hyperlinks below:

Problem Statement

Polluted air is concentrated in indoor spaces.

It is well known that cars produce carbon emissions.

In South Korea, vehicles produce around 27% of emissions. Moreover, micro-dust, consisting of carbon and metals, build up and directly harm human cells. This can lead to a shortened lifespan, birth defects, and respiratory disease.

How might we provide clean air to the passenger and reduce carbon emissions?

Current Market Trends

How the Current Market Tackles Air Pollution Within A Vehicle

Anti-Bacterial PurifiersRe-chargeable Air PurifiersThese products are high in-demand. However, these gadgets not only takes up space and uses electricity, but also there is currently no conclusive data or evidence of the products reducing air particles.

Design Opportunity

Proof of Concept– NEXO Terrarium Exhibition

This exhibition shows Hyundai Motor’s FCEV Nexo supplying plants with water produced from the hydrogen fuel cell.

Designing for the Hydrogen Fuel Cell

This electric zero-emission vehicle produces electricity using a fuel cell powered by hydrogen. This type of engine, also known as a hydrothermal engine, efficiently extracts energy from water and expels it as a byproduct. By utilizing this innovative technology, we are able to reduce carbon emissions and embrace a more sustainable future.

Instead of releasing water as a byproduct, could an internal system redirect the water and circulate it within the vehicle?

Learning from Nature

Can algae be the answer?

Exploring Nature– Which species most efficiently filters Earth's air?

Delving into researching algae under the microscope

@NatureLab– Using minimum equipment, we created our own mini wet lab cultivating microalgae!

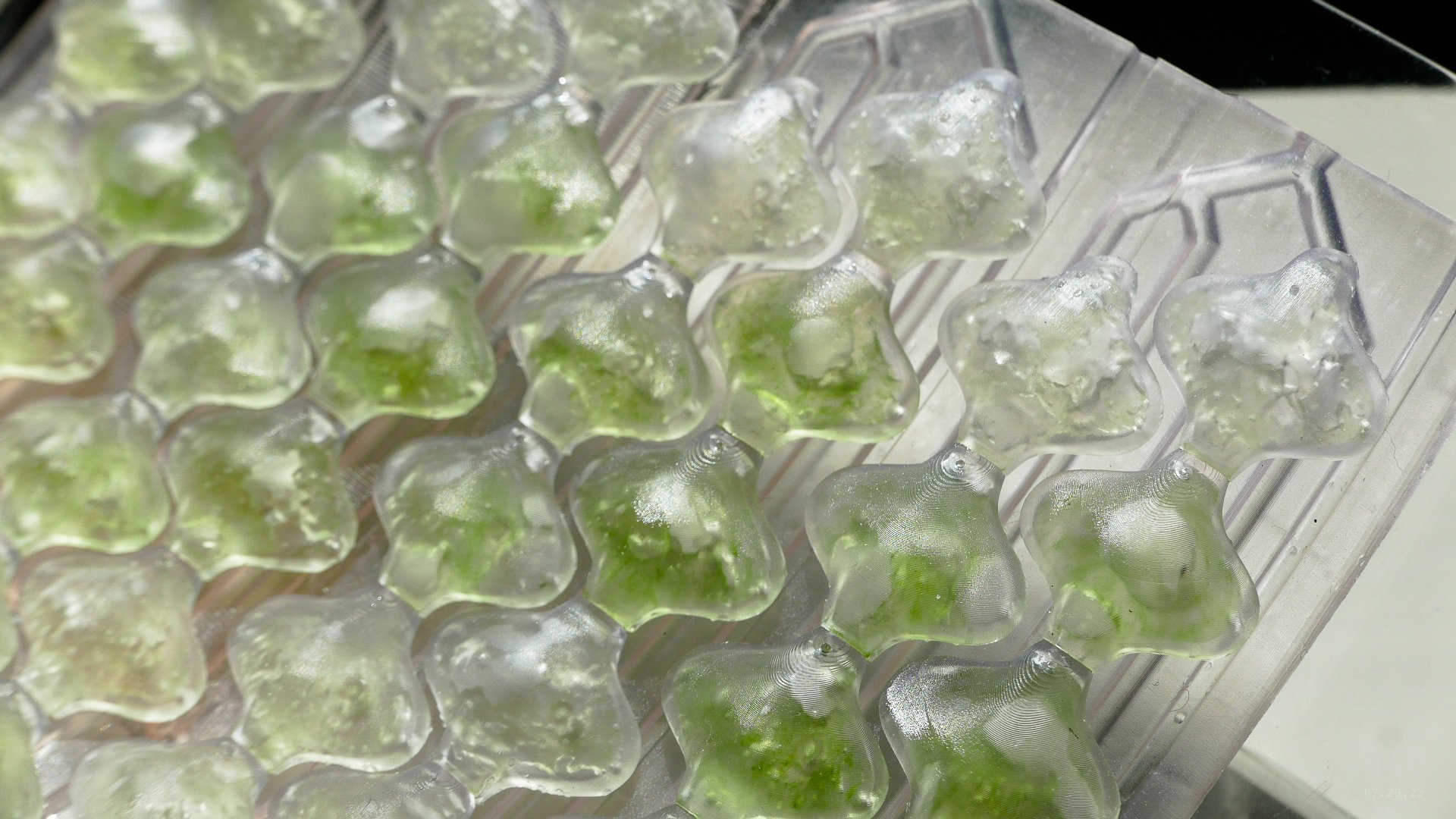

Jellifying liquid microalgae cultures with hydrogel

Talking to professionals– MIT, Northeastern, URI, Roger Williams University professionals

Proof of Concept– Using professional PAM equipment, we proved the efficiency of air filtration via photosynthesis

Can we plant or propagate algae into a vehicle to provide clean air for the passenger?

3.

Design

Constraints

Due to large panoramic sunroofs and the problem of no sun protection and shade for the passenger, it opened up the chance for our algae material to be incorporated into these specific areas (highlighted in green circles).

After rudimentary site visits and gathering professional insight on utilizing algae for air purification, we advanced our vision on designing an optimal design form to house our algae culture.

Optimizing Volume

Allow for Gas Exchange

Modularity

Current Market Trend Pain Points

Panoramic sun roofs are in high demand where larger glass surfaces cover the ceilings and the passenger’s periphery.

Although this design trend allows a wider view and immersive experience, it is important to note that this design causes:

a rapid increase of indoor temperature.

exposes the interior to an excessive amount of heat, resulting in damaged interior components.

exposed the passenger to no sunshade or protection, causing discomfort.

Departure Points– Form Inspiration

We focused on the various patterns that exist in algae. From diatoms to macroalgae, the orderly arrangements of each cell or chloroplast was our main source of inspiration. The joinery between each translucent cell of spirulina and the modular arrangement of macroalgae were two focal points when considering surface area and pattern exploration. Emulation– Pattern Exploration

Organic Curves, Interconnected Components, Aesthetically Links Together

Final Design of Modules

The solar curvature analysis visualizes the optimal curvature to hold living algae to allow photo efficiency on a flat and broad volume.Proposed Design

Iterations of Algae Culture Vessel–

We explored numerous shapes and valve connections through CAD modeling and curve analysis to find the more optimal designs to further our study. The final design was an inflated, modular, and organic structure.

Final Design of Channeled Base

Similar to our blood vessels, this base enables vascularization with hollow channels, which allow gas, liquid, and nutrients to reach each module.3D Printing Prototype

We used flexible resin to create a real-scale and working assembly of the vessels and base using high resolution 3D printers. Due to the malleable nature of this material, we were able to successfully create air-tight joinery between module-module and modules-base.

Additionally, the flexible resin material is soft and forgiving to the human touch, suitable for the interior panels in the vehicle.

Lastly, the flexible material would make it easier to efficiently remove the biomass from the algae during post-processing.

Prototype

Air Pocket

Air Pocket is a material engineered to provide the passenger with clean air, and spark a visual and sensory curiosity for the power of nature.

The System– Contextualizing Air Pocket